- 手机:186-3198-5235

- 电话:133-6377-0388

- Q Q:50887197

- 邮箱:50887197@qq.com

- 地址:河北省邢台市内丘县南工业园区复兴路19号

线材调直机如何正确快速调直线材说明书

作者:小编 发布时间:2024-04-11 14:04:58 点击量:

线材调直机如何正确快速调直线材说明书

How to correctly and quickly adjust the wire rod straightening machine

1调直机讲解 Explanation of straightening machine

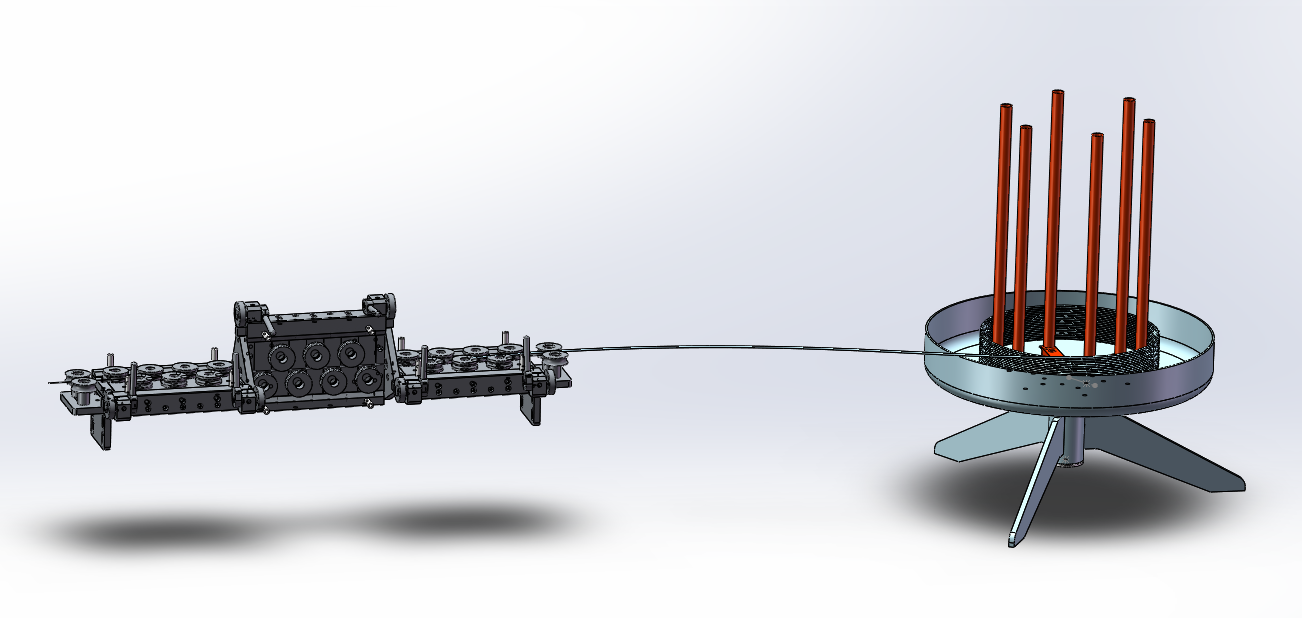

线材调直机分为两组,三组和四组,每组有少轮组和多轮组之分。

Wire straightening machine is divided into two rollers , three rollers and four rollers, each rollers is divided into less rollers and more rollers group.

少轮组 Less rollers

进线方向 feeding wire direction

多轮组More rollers

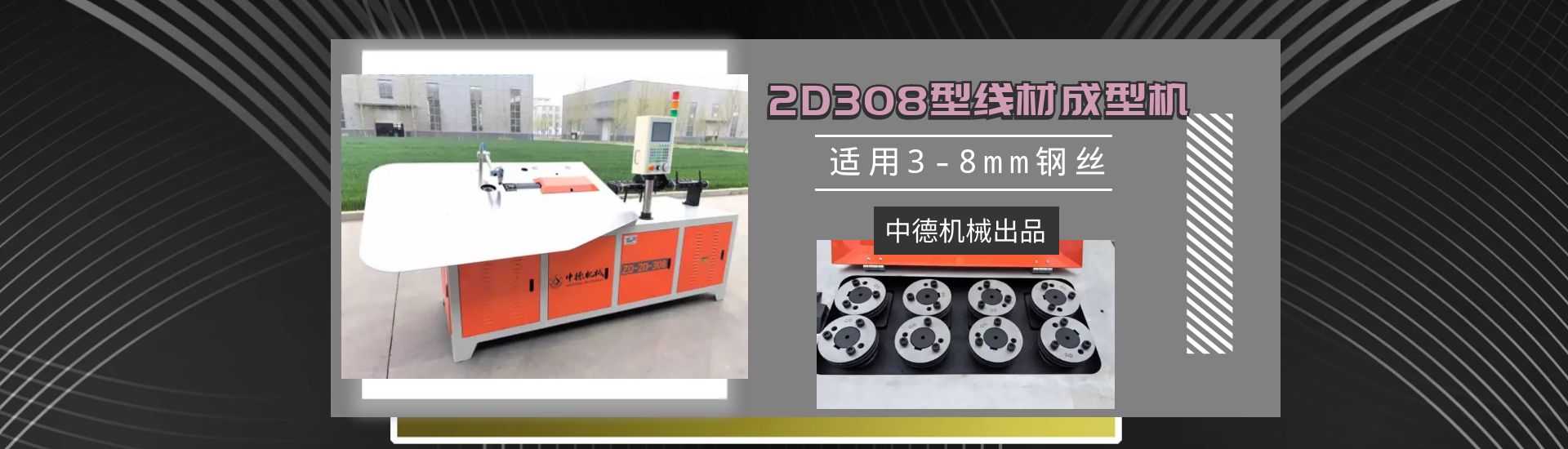

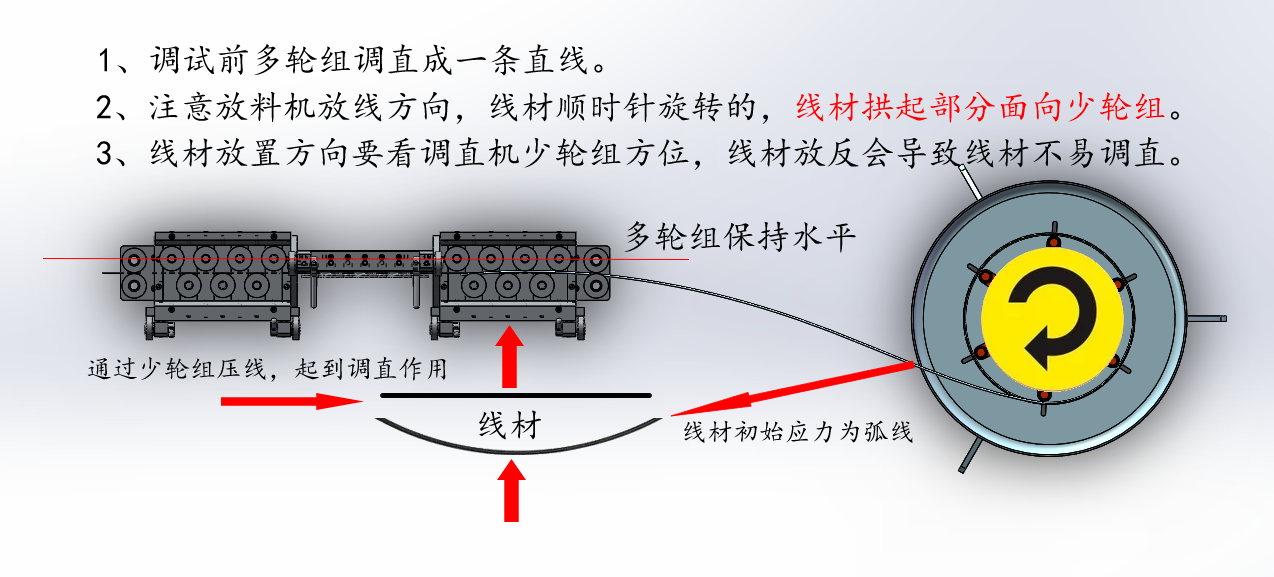

2线材一般都是盘料,想要达到调直效果,必须用调直机减掉线材应力,线材调直前要注意线材是顺时针还是逆时针送线,在调直前要观察调直机少轮组和多轮组位置,线材拱起方向是少轮组,为避免送线错误,请看下面示意图。

The wire is generally coiled. In order to achieve the straightening effect, the wire stress must be reduced by the straightening machine. Before the wire straightening, pay attention to whether the wire is sent clockwise or counterclockwise. Before the straightening, observe the position of the less roller group and multi roller group of the straightening machine, and the arch direction of the wire is the less roller group. In order to avoid wire feeding error, please see the following schematic diagram.

1、调试前多轮组调直成一条直线。

Before commissioning, multiple wheel sets shall be straightened into a straight line.

2、注意放料机放线方向,线材顺时针旋转的,线材拱起部分面向少轮组。

Pay attention to the setting out direction of the discharging machine. When the wire rotates clockwise, the arched part of the wire faces the few roller group.

3、线材放置方向要看调直机少轮组方位,线材放反会导致线材不易调直。

The placing direction of the wire rod depends on the orientation of the few rollers group of the straightening machine. The reverse placing of the wire rod will make it difficult to straighten the wire rod.

多轮组保持水平

Keep the multi wheel set horizontal

通过少轮组压找,起到调直作用

Through the pressure finding of the few wheel group, it plays the role of straightening

线材 wire rod

线材初始应力为弧线

The initial stress of wire rod is arc

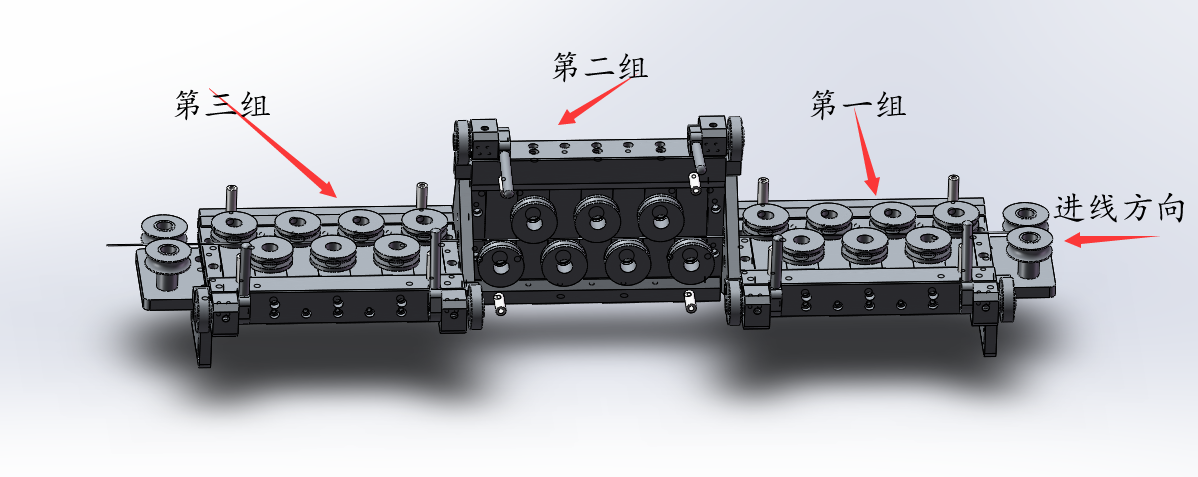

3.调直机结构组成和调直原理

Structure composition and straightening principle of straightening machine

1

进线方向:feeding direction

第一组: first group

第二组: second group

第三组:third group

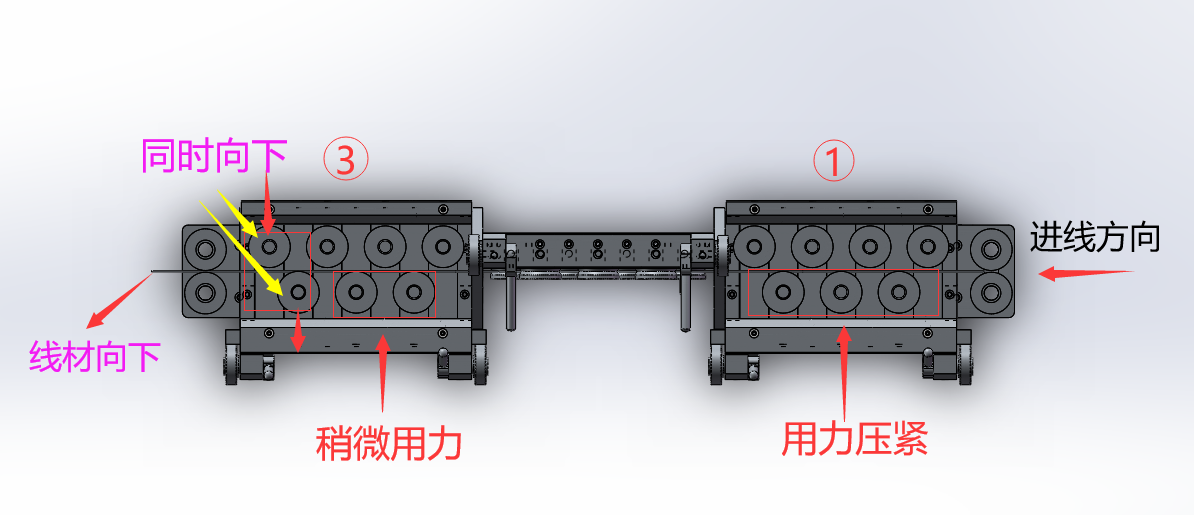

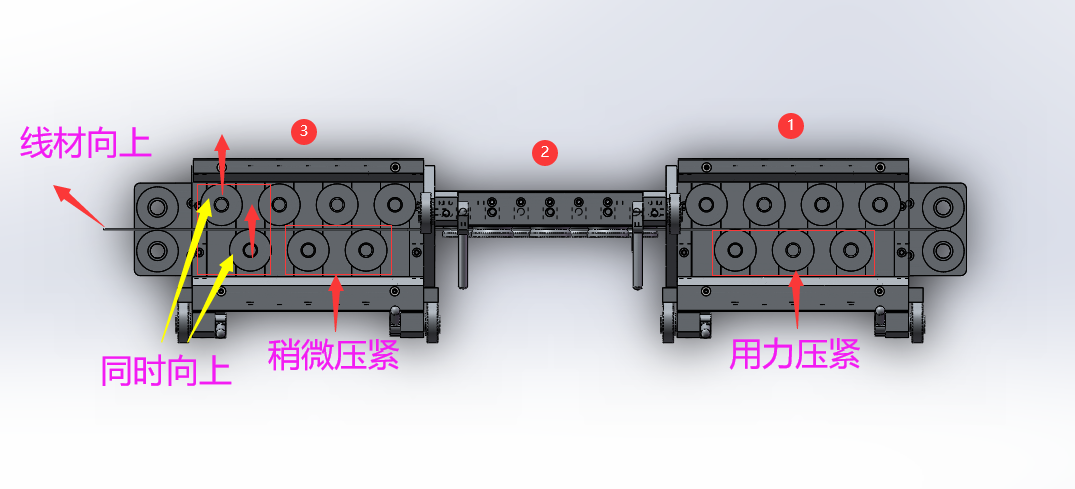

一组和三组组件使用方法:①组多轮组在调整为一条水平直线后,穿入线材,用少轮组压线材拱起部分,压紧少轮组,穿过整个调直机后,③组下方两个少轮组稍微用力压紧,用来抵消因为①组调直机部分未调直线材应力,③组最左侧两个轮同时向下(左)和同时向上(右)可以调整线材向下(左)和向上(右)的方向。

Usage of the first group and the third groups of components: ① after adjusting the multi rollersgroup into a horizontal straight line, feeding the wire rod, press the wire rod arched part with the few wheel rollers, and press the few roller group. After passing through the whole straightening machine, press the two few roller groups under other group ③ slightly to offset the stress of the straight line material in the part of group ① straightening machine, ③ The two leftmost rollers of the group can adjust the downward (left) and upward (right) directions of the wire at the same time.

同时向下adjust wire roller down at same time

进线方向 feeding wire direction

线材向下 wire down

稍微用力 Use a little force

用力压紧Press hard

线材向上 wire up

同时向上 up at same time

稍微压紧 tight slightly

用力压紧 tight stictly

进线方向 wire feeding direction

中间轮组一般用力较小,少轮组压多轮组(适度用力),最左侧两个轮组同时向上或者向下会引导线材向上或者向下。

The force of the middle rollerl group is generally small, and the less rollers group presses the more rollers group (moderate force). The two roller groups on the leftmost side will guide the wire up or down at the same time.

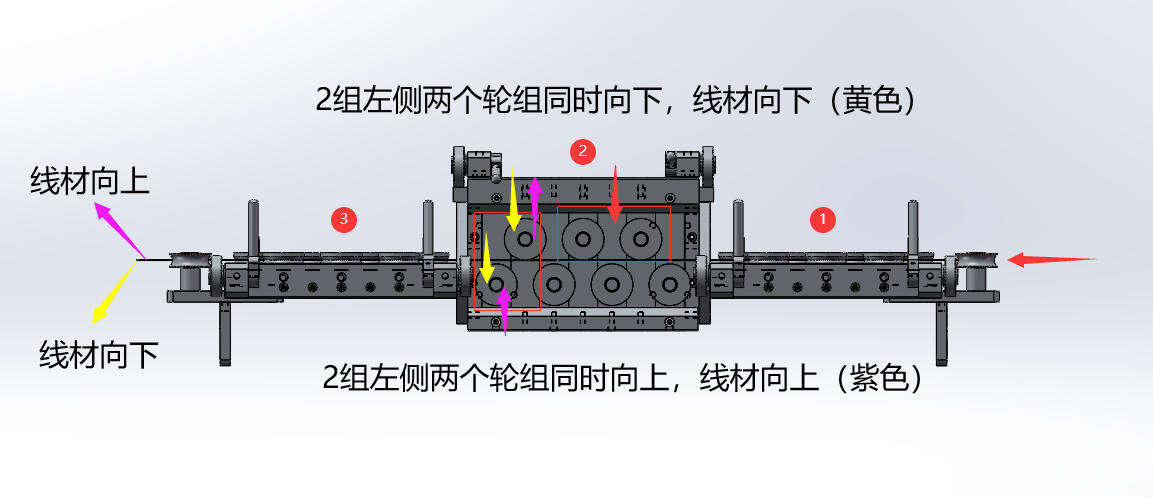

2组左侧两个轮组同时向下,线材向下(黄色)

Two sets of left rollers wheel sets are downward at the same time, and the wire is downward (yellow)

线材向上 Wire up

线材向下Wire down

2组左侧两个轮组同时向上,线材向上(紫色)

The two sets of rollers wheel on the left side of the two sets are upward at the same time, and the wire is upward (purple)

4线材调直要根据线径和线材硬度适度调整压紧程度。另外一定要分清进线方向以免导致调直时间过长。希望通过讲解能够帮助到您,能够快速解决线材调直问题。

The wire rod straightening shall be properly adjusted according to the wire diameter and wire rod hardness. In addition, be sure to distinguish the incoming line direction, so as not to cause too long straightening time. I hope the explanation can help you and quickly solve the problem of wire straightening.

推荐产品 MORE+

推荐新闻 MORE+

- 2D弯线机和3D折线机的应用范围?2020-09-17

- 弯线机有那几种?2020-09-17

- 折弯机厂家告诉您折弯机的原理2020-09-17

- 线材折弯机做宠物笼子成型2020-09-17

- 降低线材折弯机损坏的方法是什么?2020-09-17

- 数控自动折弯机轴芯出现问题怎么处理?2020-09-17